3 things to consider when automating bin picking

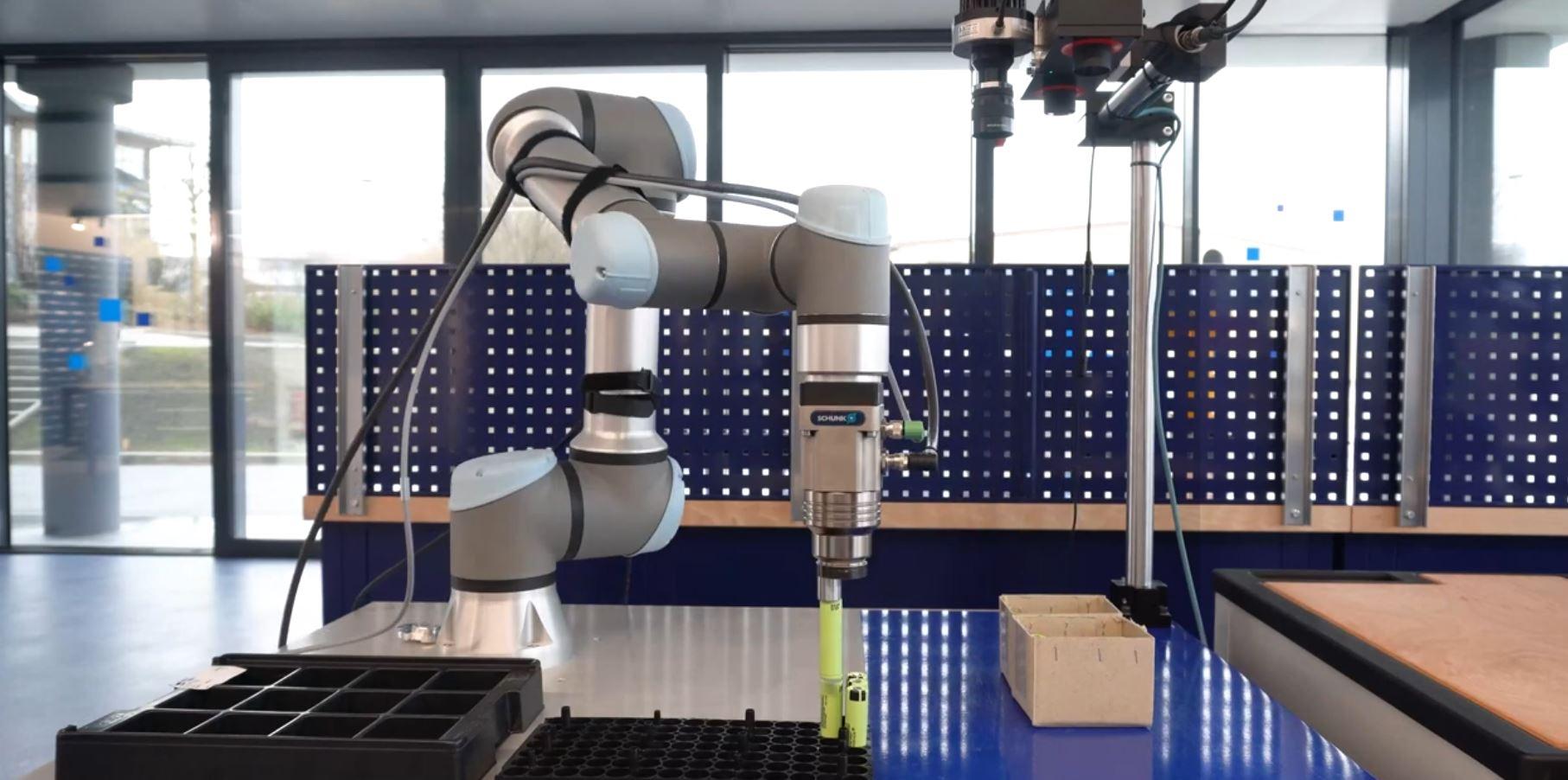

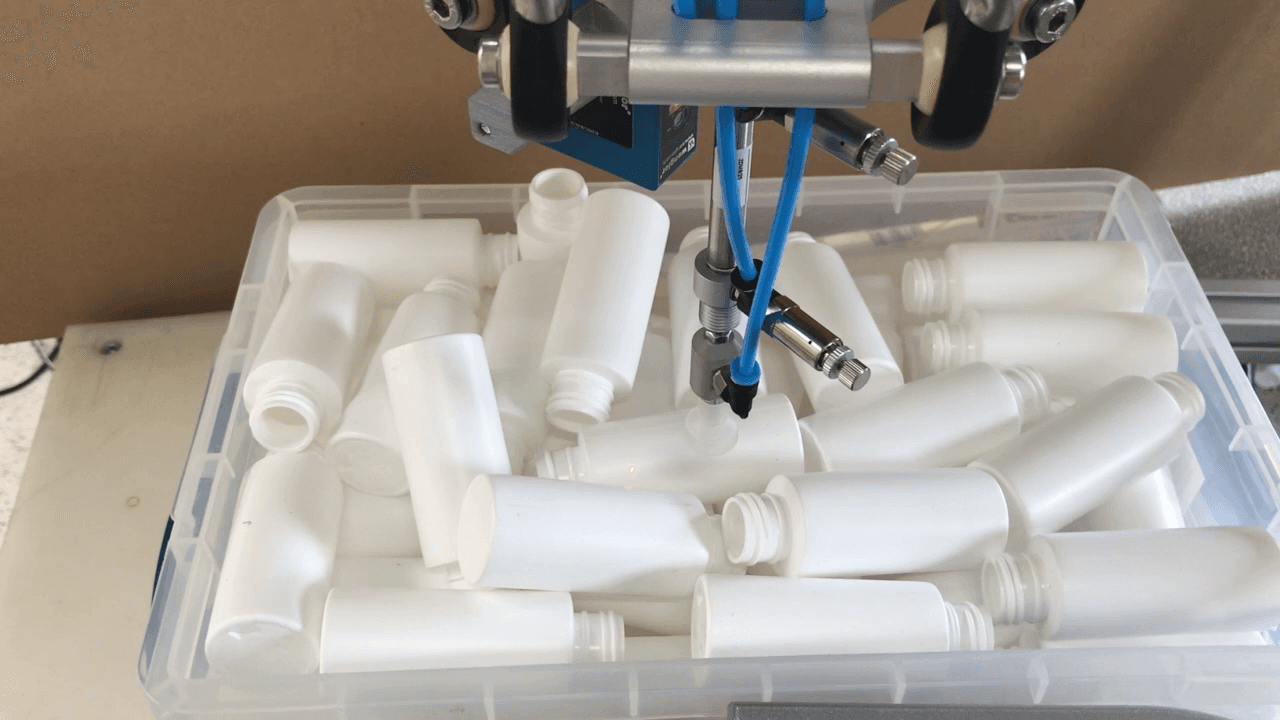

In many production and logistics processes, removing unsorted parts from containers – known as bin picking – is one of the biggest challenges. Different shapes, layers and positions of the components make automated removal complex. However, modern robotics combined with 3D image processing and AI-supported gripping planning makes exactly that possible.

With the bin picking solutions on the RBTX marketplace from igus, you get cost-effective, ready-to-use systems that reliably master even complex picking scenarios – ideal for SMEs and industrial companies that want to make their processes more efficient.

3 things to consider when automating bin picking

Analyze part geometry and material properties

The shape, size, surface, and weight of the parts to be picked influence the choice of gripper and image processing. Shiny or transparent parts, for example, require special 3D cameras or light sources.

Select the appropriate 3D vision technology

Precise object recognition is crucial for reliable bin picking. This is where 3D cameras (e.g., time-of-flight, stereo cameras, or structured light) come into play, capturing the position and orientation of the parts in space.

Coordinating grippers and path planning

The gripper must not only grasp the part securely, but also avoid collisions with the container. Intelligent path planning ensures that the robot operates efficiently and safely – even in changing scenarios.

How to get started with your bin picking solution

Discover the key steps to automate bin picking tasks — from selecting the right components and 3D vision systems to configuring grippers and optimizing system setup for reliable performance

Define the application

Which parts need to be picked? How big is the container? What cycle time is required?

Select components

The RBTX marketplace offers robot arms, 3D cameras, grippers, and software solutions—all modularly combinable and coordinated with each other.

Test & validate

Use the RBTX “test before invest” service to have your application tested. This will give you a realistic assessment of feasibility and performance.

Integration & commissioning

Many systems are “plug & play” – with intuitive software, preconfigured interfaces, and support from igus and partners.

RBTXpert Conclusion

Bin picking is impressive—but it takes time to set up and optimize. You’ll need the right camera, lighting, gripper, and patience. Plan for setup time and budget. If you need a fast solution, consider pre-sorting. But if you're ready to invest, bin picking can save serious effort in the long run.

Advantages of the automated bin picking solutions

Automated bin picking increases speed, accuracy, and consistency while reducing labor costs, fatigue, and the risk of handling errors

24/7 operation possible

Robots work around the clock – without fatigue or errors.

Consistent quality

Every pick is perfect – regardless of daily form or experience.

Higher process speed

Automated picking speeds up downstream processes such as assembly, packaging, or sorting.

Reduction of waste and damage

Precise gripping movements minimize mispicks and component damage.

Relief for employees

No more monotonous, physically demanding work on the line.

Get started, find your solution now!

igus

Fairino

igus GmbH

Mech Mind

Variobotic

SCHUNK

Variobotic GmbH

PanAromaGmbH

FAQ

Frequently asked questions about bin picking with robots